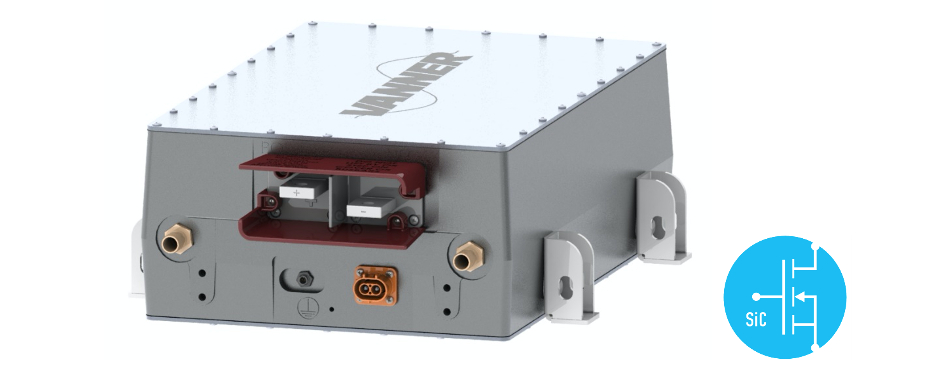

Vanner Begins Serial Production Of 17.1 kW, 600 Ampere 600VDC To 24VDC Liquid-Cooled Converter For ZEV And Hybrid Vehicles

Vanner Inc., has announced the beginning of serial production of the company’s latest 17.1 kW, 600VDC to 24VDC liquid-cooled converter with Silicon Carbide Solid-State Switching (SiC) for ZEV and hybrid vehicles.

“This technology builds on our legendary 300 ampere 600VDC to 24VDC air-cooled converter. Named the Hybrid Beltless Alternator™ (HBA™), the 300-ampere air-cooled converter has been in serial production since 2011, and has been used by OEMs New Flyer, Gillig, Nova, ENC and Tata. It is a main product for Vanner. Stringent testing and validation were performed, including 2010 vehicle validation in the desert of Death Valley, California,” according to a press release.

The release added: “There is an increasing need for more accessory electrification, extended vehicle range, and the need for a reduction in converter size. Vanner designed a 17.1 kW, 600-ampere converter with SiC switching for highest efficiency. This converter is liquid-cooled to minimize the footprint for a converter this size. It is IP67 rated. In 2022, Desert Thermal Endurance Testing was conducted.”

“Vanner Inc. introduced our air-cooled DC to DC converter in 2011. It has an electrical efficiency between 92% – 96%. This compares to belt-driven alternators that can have efficiencies as low as 50%. With our new converter using Silicon Carbide (SiC) and our engineering implementation, electrical efficiency operates between 96% -98%. This near 100% efficiency is especially important when heavy duty zero-emission vehicles are looking for efficiency gains to extend their operating range,” Alec Cook, VP Engineering and CTO, Vanner Inc., said.

Models:

- Liquid-Cooled Hybrid Beltless Alternator (LCHBA) for hybrid vehicles; and,

- Liquid-Cooled Electric Beltless Alternator (LCEBA) for battery and fuel cell vehicles.

“When combined with a Vanner 80-Series Equalizer with Model Based Battery Monitoring (MBBM™), the converter will automatically adjust its output to optimize 12/24VDC battery charging, based on Vanner algorithms that continuously calculate State-of-Charge and State-of-Health. These products offer a CAN communication interface besides being compatible with our Dashboard diagnostic software,” the release said.

For nearly 50 years, Vanner has been an engineer, designer, and manufacturer of customized, proprietary power conversion, energy management, and communication systems — such as electric hybrid electrification systems, inverters, equalizers, alternators, isolators, and converters — for commercial vehicles. Vanner’s headquarters and manufacturing are in Hilliard, OH. For more information, visit vanner.com.